CASE STUDY

Radial Staker Box Beam

Exposed Surface Coatings

Project Data

| Location | Port Hedland, Western Australia |

| Asset Owner | Dampier Salt (DSL) |

| Products | Denso Steelcoat 400™ System |

| Date | 2017 |

Project Details

Dampier Salt (DSL) approached us late last year for a long term solution to protect a fabricated box beam that will be installed in a high salt spillage area on a radial stacker. This is a highly corrosive area that was determined to require a higher level of surface protection than a typical blast and paint solution. The Denso Steelcoat 400™ system was specified to extend the life of the beam due to its ability to exclude the environment from the underlying steel beam.

The Steelcoat 400 system consists of:

- Primer D: A bitumen primer designed to aid in the adhesion of bitumen tapes.

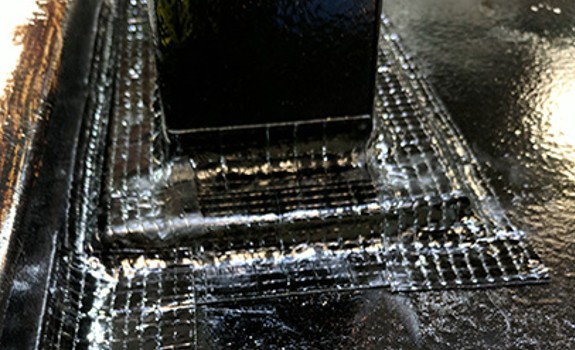

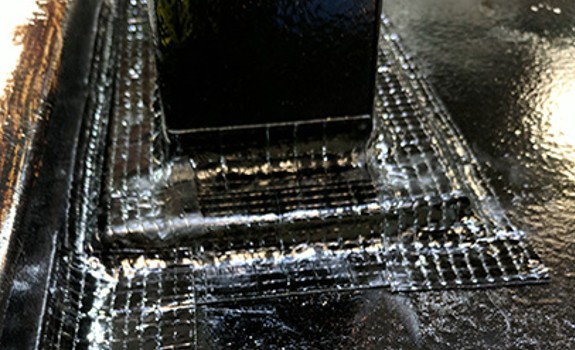

- Conforming tape: An open weave fibreglass mesh backing coated with a blended bitumen polymer adhesive compound, used for detailing on complex shapes.

- Ultraseal Tape: An acrylic coated non-woven fabric backing coated with a bituminous adhesive compound.

- Acrylic Topcoat: A pigmented, water based high opacity acrylic paint.

Dampier Salt (DSL) has three Salt operations in Western Australia located at Dampier, Port Hedland and Lake Mcleod. Salt production is achieved by pumping seawater through progressive ponds resulting in concentration via evaporation. The salt is harvested and then transported to the wash plant by 180 tonne, bottom dump trucks. Thereafter, the salt is washed to remove insoluble materials and fed onto a static screen where brine and seawater sprays remove the residual liquor that surrounds the salt crystals. The product salt is then fed onto a radial stacker, which moves through an arc of 180 degrees to form a stockpile with storage capacity of over 750 000 tonnes.

The completed box beam.

Ultraseal Tape Application.

Conforming Tape for profiling complex shapes.

The completed box beam.

Ultraseal Tape Application.